contactor failure analysis

The coil in the contactor is energized to make the armature magnetic and the suction armature drives the moving contact and the static contact to close. The chattering sound can be heard when the plunger is trying to make contact but is unable to do so completely.

Contactor Failure Symptoms Reasons For Contactor Failure

Chattering the plunger tends to chatter when the contacts are dirty or when the coil has become weak.

. The results include Maximum Allowable Working Pressures MAWP calculated for the original design with a 116th corrosion allowance and with zero corrosion allowance for actual measured conditions. All contactors were installed in the same cabinet. Current peaks used by heavy duty starting - If the application requires a high level.

The possibility exists for any construction contractor to fail to filfill the contract requirements associated with a facility. The characteristic map through its infrared thermal characteristic map can easily find the. This factor should not be overlooked for it can make the difference between success and failure for a given contact set.

Design Pressure 643 psi Design Temperature 650 F Shell Head Materials A212 Gr. 2 Check whether the contacts of the start button are in poor contact. Firstly the test device and the test parameters are introduced in brief.

With decades of experience in designing full and semi-custom test contactors the Y-RED combines. The possibility exists for any construction contractor to fail to filfill the contract requirements associated with a facility. Coil The contactor will have a coil.

Direct on line across-the-line motor starting. Too high continuous control voltage could also cause the coil to melt. In the test three normal contactors and one damaged contactor were used.

Open the contact box and check if the contact is not. The following is an analysis of the coil failure. Monitoring the condition of the contacts may be quite expensive and may not be that reliable.

See picture below for typical failure. In addition to IC chip evaluation and validation the focus is now on failure analysis applications and low inductance laboratory measurements. Secondly test plan is given.

It is used to complete the operation stopping and speed. This paper provides aggregate contractor. When users evaluate and measure the parameters of electronic components after long-term.

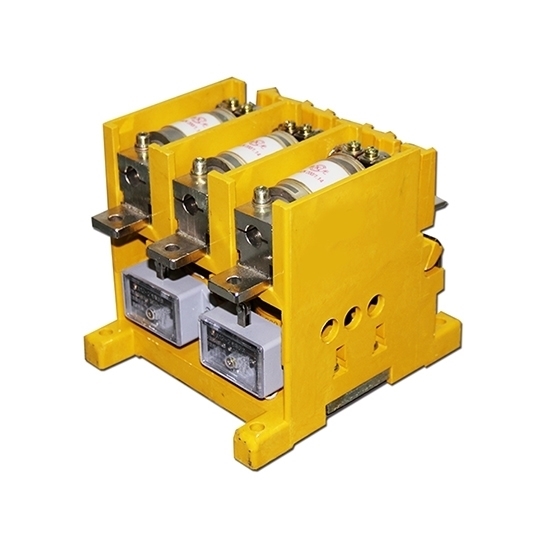

So its reliability level is very important. Analysis of common failure principles of electric forklift contactors Forklifts are widely used in cargo handling and transportation in cargo yards warehouses and ports due to their flexibility low noise and no pollution. High contact erosion If electrical contacts are eroding too rapidly review all of the factors listed in the contact welding section above because the same factors can cause increased erosion rates even if the conditions are not severe enough to.

Insertion fault The coil is burned out by excitation rush current 1015 times of holding current flowing into the coil if you operate it continuously without perfect inhalation after the power voltage decreases abnormal material penetrates the magnetic contact pole. This type of fault usually occurs after the line is short-circuited. For example on time.

This paper provides aggregate contractor business failure statistics and outlines. The corrosion of contact resistance caused by different breaking current is determined by accelerated test or life cycle data. The simplest method is to use a precision resistor as a shunt and simply measure the voltage across it.

Then the coil is broken which will naturally cause the contactor to fail to close. Nozzles flanges and fittings were all evaluated. The main contact part is ablated the contact surface is uneven or there is oxidized metal attached.

Contractor failure occurs when a contractor is unable to perform hisher contractual duties thus requiring the facility owner to invoke the contracts nonperformance clause. IC Test Contactor for Failure Analysis. The main contact resistance is too large.

Alternating current contactor is one of the important elements widely used in the automatic control system. If there is no resistance it must be broken. Examples of common reasons for contactors not working properly is causing the voltage to drop.

It al- so is less than desirable for. The common contactor coil failures are. Waross Electrical 15 Jul 18 1621.

Contractor failure occurs when a contractor is unable to perform hisher contractual duties thus requiring the facility owner to invoke the contracts nonperformance clause. The electrical contact failure has been one of the main aspects that affect the storage reliability of the components. Secondly test plan is given.

Coil failure and repair. This paper mainly concerns failure analysis of the failure contactors after the reliability trial of AC contactor. Can not be closed after power on 1 Check whether the coil power supply circuit is open and reconnect the disconnection point.

The method is very accurate but can generate considerable heat in highcurrent contactors. Lastly the failure reason is analyzed for each failure sample in detail from different way. The damaged contactor contactor A has a broken bolt in the lower moving part although it can be opened and closed.

Therefore whether the coil is strong or not plays an important role in the reliable connection of the contactor. This mechanism is designed to ensure that the circuit is safely opened in a failure such as a power failure. After the coil is energized the moving contact can be attracted to make it contact with the static contact so that the contactor can be closed.

Analysis of common faults of AC contactors. This paper mainly concerns failure analysis of the failure contactors after the reliability trial of AC contactor. According to the test plan sixteen samples are chosen to test.

Welding happens but is often associated with fault currents and so is independent of contactor age or wear. The overwhelming number of failure of motor contactors are failure to close. The Connector Basics series from APEX Electrical Interconnection Consultants continues with an introductory look at typical connector failure modes and mechanisms.

The DC contactor is an important device in the electrical system of electric forklifts. The normal opening and closing of contactor is one of the important indexes to realize its function but with the increase of opening and closing times the performance of contactor gradually decreases 5 2. Download Citation Failure Analysis of Alternating Current Contactor Alternating current contactor is one of the important elements widely used.

Use a multimeter to measure the coil resistance. According to field investigation and previous contactor failure analysis the contactor failure is mainly caused by loose terminals contact oxidation dust leakage and overload operation. Common faults of contactors 1.

21 May 2021 - The Y-RED test contactor series from Yamaichi Electronics is growing. Firstly the test device and the test parameters are introduced in brief. There are 3 main signs which indicate a bad contactor in your AC.

Figure 3 shows the infrared heat when the contactor is abnormal. Analysis of common failures of AC contactors 1. AC Contactor Failure Symptoms.

The analysis of the storage of electromagnetic relay is helpful to improve the reliability of components which need to undergo the long-term storage. A method to monitor running current through the contactor accurately is thefirst requirement for electronic overload protection.

Reasons Of Contactor Failure Contactor Troubleshooting Youtube

Test Method For Judging The Quality Of Ac Contactor Guangpu Electrical Co Ltd

What Can Be Caused By Contactor Failure China Nanfeng Electric

Reasons Of Contactor Failure Contactor Troubleshooting Youtube

What Can Be Caused By Contactor Failure China Nanfeng Electric

What Can Be Caused By Contactor Failure China Nanfeng Electric

Contactor Failure Symptoms Reasons For Contactor Failure

Common Reasons For Contactor Failure

New Contactor Wiring Diagram Single Phase Servisi Co

Case Study How Auxiliary Contactors Mounting May Result Into Mal Operation Tripping

Common Reasons For Contactor Failure

Contactor Failure Symptoms Reasons For Contactor Failure

What Causes A Contactor To Fail Youtube

Contactor Failure Symptoms Reasons For Contactor Failure

What Can Be Caused By Contactor Failure China Nanfeng Electric

3 Phase Ac Vacuum Contactor 200a 1140v Ato Com

Contactor Failure Causes And Maintenance

Real Cases Of Magnetic Contactor Failure Impact On Power Plant Process Possible Causes Of Failure Corrective Actions Taken Comprehensive Overview

0 Response to "contactor failure analysis"

Post a Comment